Weight/Statics: Facts & Fake News

Generally, you can rely on the structural engineering of a house. This means that even very heavy items with high point loads can usually be installed without problems: whether a grand piano (up to 700 kg), a waterbed (up to 900 kg) or an aquarium.

This is especially true for soundproof booths. The topic is also rife with myths. "Quick calculations" and assessments by non-experts often lead to fundamentally flawed results. In other words, classic fake news.

For accurate information, we recommend referring to the relevant DIN standard 1055-3 (Eurocode 1). However, in case of doubt (e.g., with very old wooden ceilings), you should consult a structural engineer. They will determine each point load separately and relate it to the uniformly distributed live load.

How is my biological sleeping cabin built?

Our experience from more than 30 years

Since the early 1990s – the time STUDIOBOX has been around – we are not aware of a single case where a ceiling has been damaged or even collapsed due to the weight of our booths. Nor have we received a single report that the load-bearing capacity test by experts failed to pass.

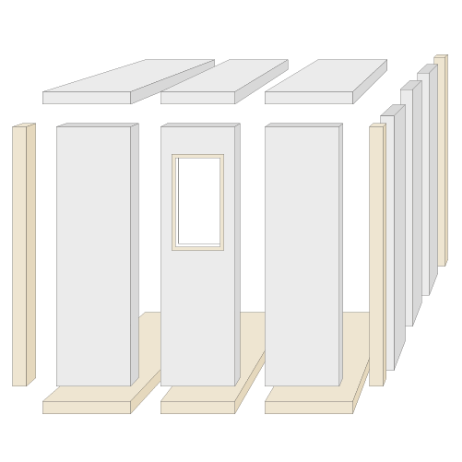

Contrary to popular belief, the weight of the cabin is not distributed one-to-one (1:1) across the footprint of the box, but rather across the entire surface of the ceiling. Furthermore, nearby walls also absorb some of the load. Therefore, the load per square meter is significantly lower.

Please note, however, that we are not authorized to make binding statements regarding the construction quality of your house/apartment.